Why to Choose Industrial Scales for Accurate Weight Dimension in Different Industries

In a period where precision is extremely important, the choice of commercial scales for precise weight dimension plays a crucial function throughout varied markets. These ranges not only improve functional performance but likewise guarantee conformity with governing standards, affecting whatever from manufacturing to delivery.

Importance of Accurate Weight Measurement

In the realm of industrial procedures, the relevance of exact weight dimension can not be overstated. Accurate weight measurement is foundational across different industries, affecting both functional effectiveness and item top quality - Industrial Scales. It offers as a critical consider supply administration, guaranteeing that materials are appropriately made up, thereby decreasing waste and lowering costs

In production, accurate weight dimension directly affects manufacturing processes. Anomalies in weight can result in ineffective products or too much source appropriation, influencing general earnings. Furthermore, in industries such as drugs and food manufacturing, adherence to rigorous weight specs is vital for regulatory conformity and customer security.

Furthermore, accurate weight measurements promote reliable logistics and supply chain administration. Correctly weighed deliveries guarantee that transport prices are enhanced and that supply levels are maintained precisely, thus avoiding supply lacks or overstock situations.

Kinds of Industrial Scales

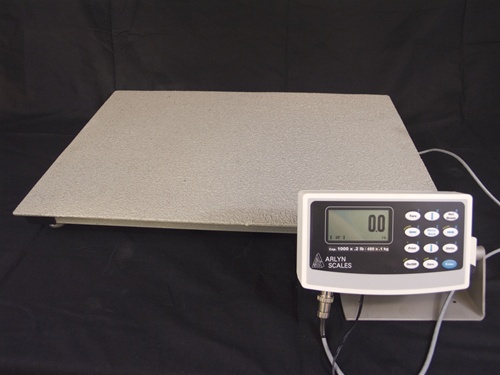

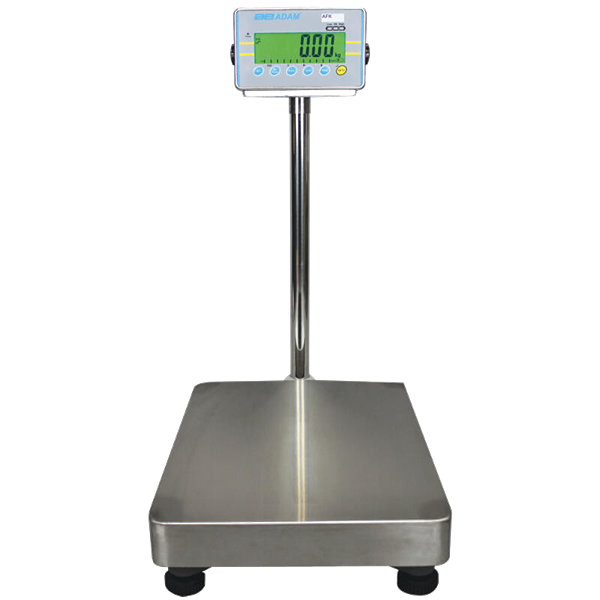

A wide array of industrial ranges are offered, each designed to fulfill particular dimension needs across varied markets. Common kinds include flooring scales, which are durable and suitable for considering large products or pallets in storehouses and warehouse. Bench scales are smaller and suitable for lighter products, often utilized in retail setups or manufacturing for specific part control.

Another classification is mobile scales, which provide the adaptability to be moved quickly around work sites, making them suitable for field procedures or short-lived setups. Precision scales, on the various other hand, are designed for high accuracy and are regularly made use of in research laboratories and quality assurance atmospheres.

Lots cells are important parts in various industrial ranges, transforming pressure right into an electrical signal for exact readings. Additionally, truck scales offer the ways to consider hefty cars and their loads, making sure conformity with laws and maximizing logistics.

Lastly, checkweighers automatically compare the weight of products against preset limits, improving top quality guarantee in assembly line (Industrial Scales). Each type of industrial scale serves a distinct function, dealing with the particular demands of industries such as manufacturing, logistics, food processing, and drugs

Advantages of Making Use Of Industrial Scales

Continually making use of commercial ranges supplies substantial benefits across various industries. One of the primary advantages is boosted accuracy in weight measurement, which is important for maintaining quality requirements and regulative compliance. Accurate dimensions protect against expensive errors in delivery, stock, and manufacturing administration, ultimately causing increased operational effectiveness.

Additionally, industrial ranges are made for longevity and effectiveness, enabling them to stand up to severe settings typically located in production and warehousing. This durability ensures a long life expectancy, reducing the demand for constant replacements and maintenance prices.

Furthermore, employing industrial scales improves safety and security and minimizes waste. By ensuring that products are weighed precisely, business can prevent overwhelming lorries, which can result in accidents and fines.

Applications Throughout Different Industries

Industrial scales play an essential function in various industries, including production, logistics, food processing, and pharmaceuticals. In manufacturing, these scales are important for ensuring that raw materials are gauged properly, therefore keeping item high quality and consistency (Industrial Scales). Accuracy in weight dimension directly affects manufacturing effectiveness and cost monitoring

In logistics, industrial scales facilitate the exact evaluating of shipments, which is critical for adhering to delivering guidelines and optimizing freight expenses. Accurate weight information helps simplify operations and boosts supply chain management.

The food processing industry depends greatly on commercial scales for conformity with health and wellness laws. They are utilized to consider components precisely, making certain that formulas fulfill both high quality standards and lawful requirements. This is crucial not only for customer security yet additionally for maintaining brand integrity.

Pharmaceutical companies use commercial ranges to make sure accurate dosages in medicine production, where also the smallest inconsistency can have considerable effects. Compliance with rigid regulative requirements makes accurate weight dimension vital in this field.

When Selecting Scales,## Elements to Think About.

Picking the right scale for particular applications calls for mindful consideration of a number of factors. The capacity of the scale is important; it needs to suit the optimum weight of the items being measured without exceeding its limits. Furthermore, the readability, or smallest increment the scale can accurately display, is vital for accuracy, specifically in markets where weight inconsistencies can result in significant financial losses or safety problems.

Ecological conditions also play a significant duty in scale option. Ranges made use of in damp or corrosive environments may call for specialized products to ensure resilience. Similarly, mobility may be essential in particular applications, necessitating read what he said battery-operated and lightweight versions.

Conclusion

To conclude, the selection of industrial ranges is pivotal for making certain exact weight measurement across diverse sectors. Their ability to provide precise analyses not only improves functional performance yet also supports regulatory conformity and inventory management. The adaptability and resilience of these scales facilitate their application in various industries, ultimately contributing to cost reduction and improved product quality. Thus, check that investing in top quality industrial scales is important for organizations intending to optimize and preserve high requirements earnings.

Comments on “How Industrial Scales Can Boost Accuracy and Productivity in Your Operations”